Budenheim, August 15, 2025 – Closures have to satisfy various market requirements, from product protection and ease of handling to sustainability. BERICAP is demonstrating the solutions that meet those needs at this year’s FACHPACK trade fair from 23 to 25 September in Nuremberg. The global manufacturer of plastic and aluminium closures is located at stand 151 in hall 6, where it will be presenting a broad product portfolio – from lightweight closures with reduced material content to solutions against counterfeiting, and tethered caps for industrial applications. BERICAP also offers comprehensive support to customers in the implementation of the EU Packaging and Packaging Waste Regulation (PPWR) – one of the central themes at FACHPACK.

Safety first and foremost

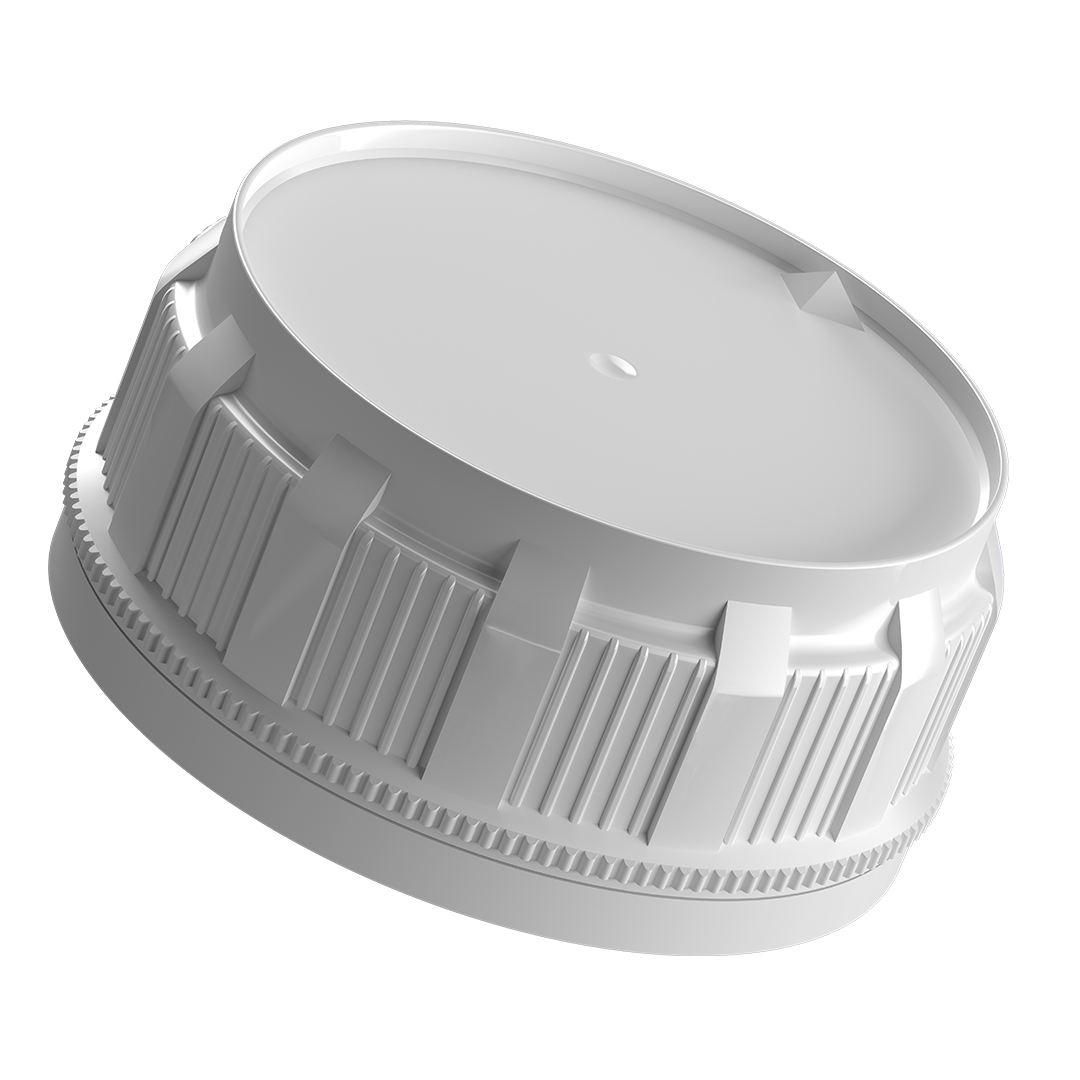

The protection of product integrity and quality is a key issue affecting the packaging industry continuously. Therefore BERICAP is continuously developing products such as the ring peel liner: a tamper-evident seal that protects the product, is easy to open by hand, reseals reliably and assures consumers the bottle has not been previously opened, combining product protection with counterfeit prevention. An additional QR code that permits a product originality check via app, as well as closure tracking, further elevate the safety level. It is even possible to integrate lenticular images into closures. Not only are they hard to copy, they also give the products a more upmarket look and thus strengthen the brand image. BERICAP offers a multi-stage anti-counterfeiting (ACF) system that allows customers to select the ideal ACF concept for their product from a comprehensive range.

Protecting the planet

BERICAP focuses on conserving resources and reducing material usage from the product development stage onwards. Those efforts have resulted in one of its trade show highlights – a “lightweight” range that is being continuously expanded. At the same time, BERICAP is increasingly using recycled materials in the production process to advance closed-loop material cycles. For example, it produces PCR (post-consumer resin) closures for use in the non-food sector. Whenever possible, mono-material designs are used to eliminate the need for additional sorting before disposal and simplify the recycling process. Tethered caps, which have been mandatory in Europe since summer 2024 for disposable plastic beverage containers with a capacity of up to three liters, are also improving efficiency in the recycling process. BERICAP’s exhibition concept for FACHPACK will be placing strong emphasis on solutions for industrial applications, such as tethered caps for canisters and plastic containers in the automotive sector. The company has extensive expertise in market-specific requirements thanks to its global presence, it operates reliable testing procedures for closures, and it provides customers with tailored consulting services.

Legal framework

The EU Packaging and Packaging Waste Regulation will be a key topic at FACHPACK. The law comes into force in 2030 with the objective of reducing the environmental impact of packaging. It will be mandatory for companies to revise the design and material of their packaging to facilitate recycling and reuse. Specific aims are packaging weight reduction and compliance with Extended Producer Responsibility (EPR) requirements. The PPWR has raised questions and caused uncertainty among some manufacturers, which is why BERICAP supports its customers with comprehensive compliance guidance.

Food and OTC products on course for growth

The trend towards health-conscious eating is having an impact on the packaging industry. Increasing demand for food supplements, nutrigenomics, and plant-based diets has opened up new growth opportunities for the health sector and the food industry. For example, manufacturers in the over-the-counter (OTC) segment are developing new product formats such as powders, tablets, and capsules. There is also a fast-growing segment of flavored fruit gums in PET containers that are primarily produced in North America. BERICAP is a one-stop provider offering advice and solutions to customers in the food and pharmaceutical industries on all packaging formats.

Broad product portfolio

BERICAP will also be presenting its wide range of aluminum roll-on closures at FACHPACK. Trade visitors to the stand can find out about special solutions for beverages, cooking oil, ketchup, mayonnaise, and spreadables.

“We are familiar with market requirements when it comes to sustainability, user-friendliness, and product safety, and we are continuously developing new solutions that optimally meet our customers’ needs. Our business partners also know they can depend on us in terms of legal issues, such as PPWR compliance. We take a solution-focused approach and will be happy to provide you with individual compliance-related advice and support. We’re looking forward to welcoming you at our stand,” said Michael Caspers, Sales Director Chemicals.

FACHPACK, a leading trade show for packaging, technology, and processes, opens its doors at the Nuremberg Exhibition Centre from September 23–25, 2025. This year’s key theme is ‘Transition in Packaging’ and the organizers are expecting around 1,400 exhibitors. The previous FACHPACK attracted 37,000 trade visitors, who came to discuss the challenges facing the packaging industry and to find out about new solutions.

About BERICAP

BERICAP is one of the leading global manufacturers of plastic and aluminum closures, with 30 production plants serving customers in over 100 countries across the world. With specialized R&D centers and its own mold shop, BERICAP is ideally equipped for the development of innovative and climate-friendly closures and to support its customers’ success with a comprehensive portfolio of products.

Best manufacturing practices at BERICAP are centrally coordinated and regularly reviewed at each plant to ensure superior quality. All BERICAP plants are certified in accordance with ISO 9001 and the GFSI benchmarking standards or HACCP. The company’s highest priorities are product safety, consumer convenience and design flexibility, as well as process safety and sustainability. BERICAP is particularly committed to material reduction through the development of lightweight designs and the use of biobased and recycled materials (PCR). In this way it is helping to conserve natural resources and close the loop in the packaging industry.